When I first had the idea to reinvent the nursing bra, I had three goals: Make it 1) chic, 2) comfortable, and 3) leakproof. The first two were accomplished through design and intensive user wear testing. The leakproof aspiration was far more tricky but we nailed it - and we have the scientific lab data to back it up.

My vision for the leakproof layer was to be invisible to the wearer by sewing the fabric into the interior of the bra cups. By making the cups non-removable, this would also eliminate the problem of loose cups and pads constantly getting bunched up within the bra and lost in the wash. (Lunnie's non-removable cups reshape perfectly with every feed and wash. The bra is washer-friendly too, a must-have for me!)

To execute this, I needed an absorbent fabric that was thin, flexible, and discrete. For the first prototype that my mom Sue and I created, we cut up fabric from absorbent period panties to test. While effective, the fabrics were far too bulky and stiff to wear in a bra.

After sourcing and testing dozens of leakproof fabrics, we finally found one that fit our criteria: An organic, absorbent fabric plus PUL layer that had the proper thinness and flexibility to fit inside a bra and felt invisible to the wearer. I conducted my own kitchen counter lab tests with an eye dropper to confirm that it had the proper absorption and drying time for a breastfeeding mom, as well as user wear testing.

While my own experiments provided a snapshot, I had the great opportunity to partner with the Stitt Scholar program at the University of Dayton to conduct thorough scientific experiments on Lunnie’s absorption versus the top five competitors. A team of faculty, engineering, and business students created two experiments to test the prolonged absorbency and total absorbency of the nursing bras.

One of my weekly Zoom meetings with the University of Dayton Stitt Scholar intern and faculty team

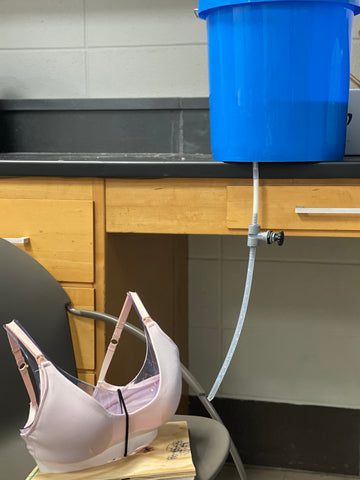

To test the prolonged absorbency, the Stitt team designed a mannequin bust that had tubing where leakage would occur inside a bra. They ran cow’s milk through the tubing at a drip rate of 1/10 ounce per a minute. Each bra was fitted to the mannequin, a timer would start, and the drip would begin. Once moisture was felt or seen on the outside of bra, the timer would start. Lunnie’s absorbency came out in first place with a rate up to 6x more absorbent than competitors.

Onsite at the University of Dayton Kettering Engineering Labs to test Lunnie's absorbency vs. competitors

To test total absorbency of the nursing bras, the Stitt team weighed each bra in its natural, dry state. The bra was then submerged in milk for 3 minutes, removed, and held until dripping ceased. Each bra was weighed after to compare the ratio of how much milk could be held in the bra compared to its dry weight. Again, Lunnie came out in first place for a total absorbency rate of 2.4x.

I knew Lunnie’s absorbency was excellent, but I was blown away by these lab experiment results. It confirmed that Lunnie’s bra is technically superior to the competition (and I would argue aesthetically superior too!). Thanks to the Stitt Scholars, I now have the data to back it up. Thanks to Grace, Tanner, DJ, Philip, and Phil for their hard work!

Lunnie’s leakproof pads can comfortably hold 1.14 ounces of milk within each cup. The absorbent layer dries quickly, allowing moms to continue wearing their bra all day. I like to describe the absorbency as a pantyliner for your bra. If you’re a heavier leaker (especially during those early newborn days), I do recommend wearing additional pads as backup.

When you wear the Lunnie Everyday Leakproof Nursing Bra, you can be rest assured that leaking is one less thing to worry about. Because between sleepless nights, keeping a newborn alive, and recovering from birth, postpartum moms have enough on their plate! I’m so excited for moms to experience and benefit from this innovative leakproof feature!

So grateful for the Stitt business grant that enabled this partnership between Lunnie and the University of Dayton